Flushing with System Pumps is not High-Velocity Oil Flushing

01 Oct 2019, Posted by in GeneralMany equipment owners believe they are removing enough contamination from their rotating equipment by flushing with system pumps. They believe that if they don’t catch contaminants in the screens and filters by use of their system pumps, the contaminants will stay dormant in the system and not cause damage. Some believe that all contaminants are removed from the system if they operate their pumps at the highest velocity possible.

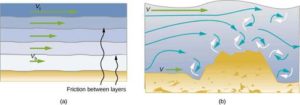

However, if you were to see inside the pipes at the lower velocities as well as the flow produced by their system pumps, you would see that these contaminants are only stirred up like the example below.

Unfortunately, they are not stirred up enough to move them all towards the screens and filters. When left in the system – these contaminants still move towards critical components during normal operating conditions, where they cause damage. If you were to see inside the pipe at over double the system pump velocity and flow, you would see properly specified high volume pumps (off-base pumps) create such turbulence and flow, that particles move towards the screens and filters where they are all removed.

Don’t make the mistake of partially cleaning a system. Your critical components will suffer for it.

McPherson Oil has teamed up with ILS to help businesses achieve maximum system efficiency. Whether it’s flushing your system or chemical cleaning, our team of trained personnel can help achieve lubrication driven reliability through many different services. Contact us today to learn more and to get started!